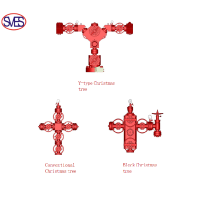

Wellhead And Christmas Tree

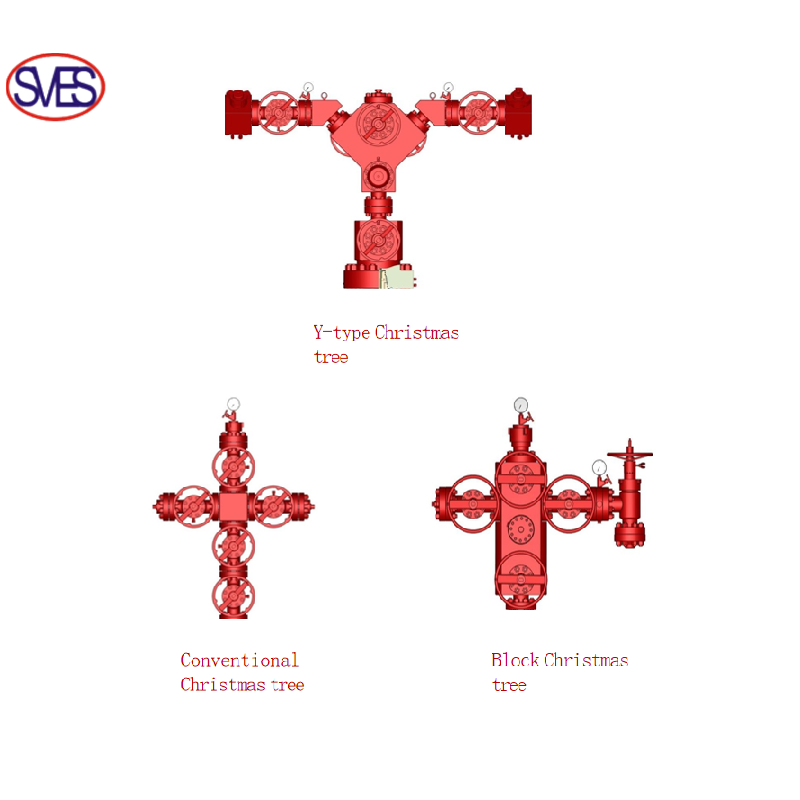

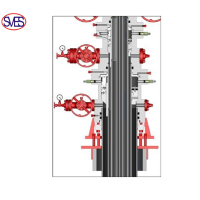

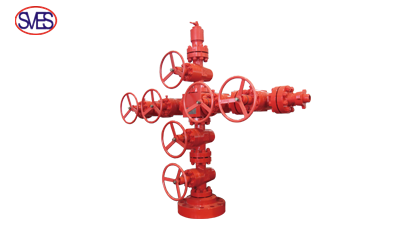

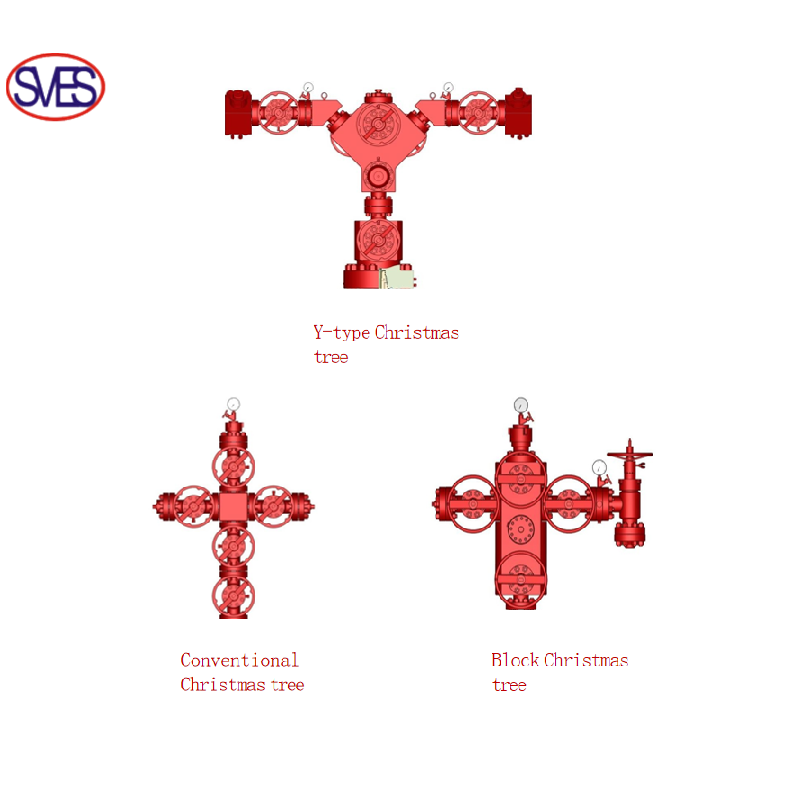

Conventional Wellhead and X-mas Tree

● Designed and manufactured strictly in accordance with API Spec 6A and NACE MR-0175 specifications.

● Compact design, reliable operation

● Rated working pressure 5000psi, 10000psi and 15000psi series available.

● Metal seal available from tubing hanger to the whole X-mas tree.

● Flanged connection.

● “VR” thread available for gate valve removal/installation,bypass valve can be replaced under pressure.

● Series tubing hangers available for various well completion needs.

● BPV and tools available.

| Performance Class | Material Class | Temperature Class | Product Specification Class |

| PR 2 | AA ~ HH | K ~ V and X / Y | PSL 1~4 |

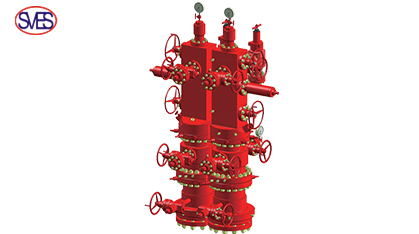

● Designed and manufactured strictly in accordance with API Spec 6A and NACE MR-0175 specifications

● Split structure applied for the whole gas X-mas tree

● Nickle alloy welded for the whole wellbore

● Tubing hanger designed with metal sealing

● Secondary seal designed with metal sealing

| Performance Class | Material Class | Temperature Class | Product Specification Class |

| PR 2 | AA ~ HH | K ~ V and X / Y | PSL 1~4 |

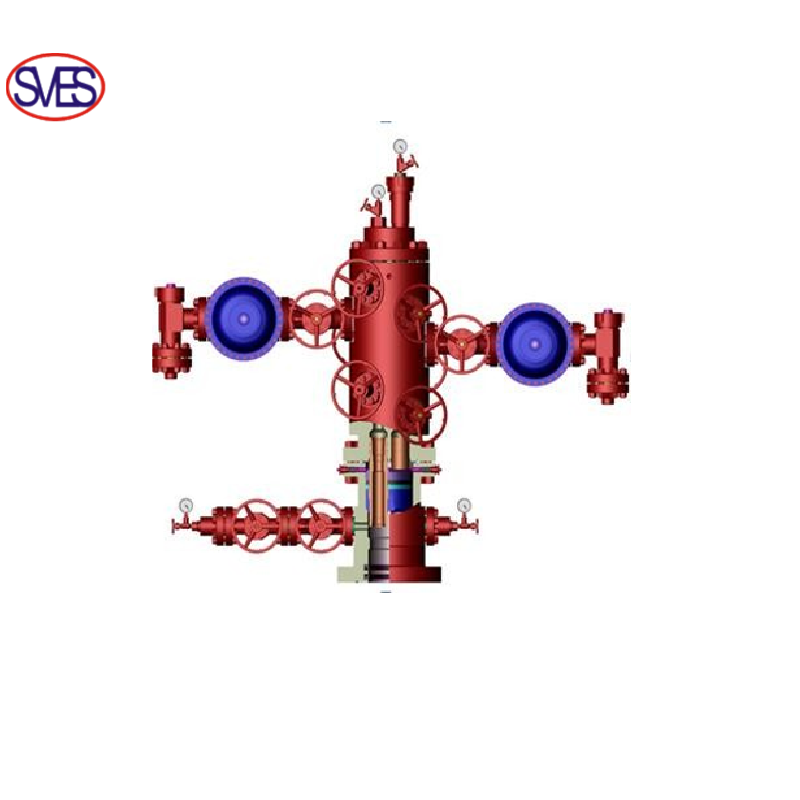

Two-in-one wellhead system adapts compact wellhead technology and produces oil from different layers seperately in the same well under dual-casing & tubing system.The main structure is to place two comparallel casing strings and tubing strings inside the same surface casing, both tubing strings are separated by dual-tubing hanger. Integrated X-mas tree seated above with compact design & good sealing performance.

| Performance Class | Material Class | Temperature Class | Product Specification Class |

| PR 2 | AA ~ HH | K ~ V and X / Y | PSL 1~4 |

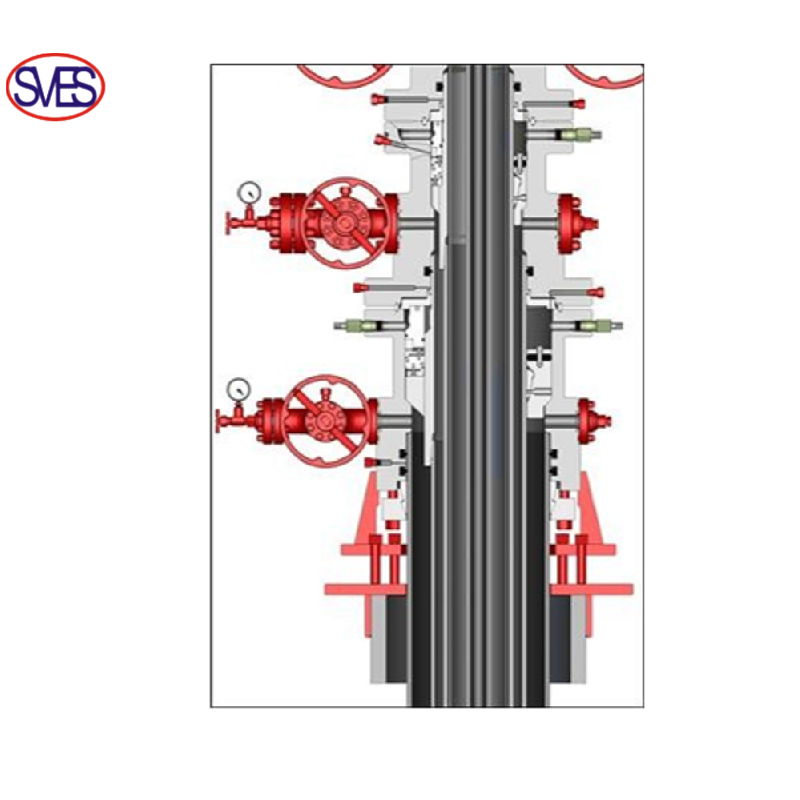

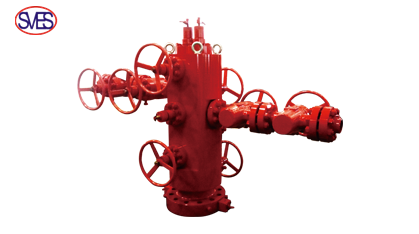

High Pressure Large Wellbore Fracturing X-mas Tree

Fracturing X-mas tree is one of the most important components fracturing equipments, it is consisted with several fracturing gate valves and fracturing goat head.The fracturing liquid is pumped into the fracturing goat head through several fracturing manifold, then pumped to the bottom of well to perform the fracturing service on designated formations through fracturing gate valves. The open and close of fracturing gate valves is used to control the fracturing liquid.Main bore size: 7-1/16”, max working pressure: 15000psi.

| Performance Class | Material Class | Temperature Class | Product Specification Class |

| PR 2 | AA ~ HH | K ~ V and X / Y | PSL 1~4 |

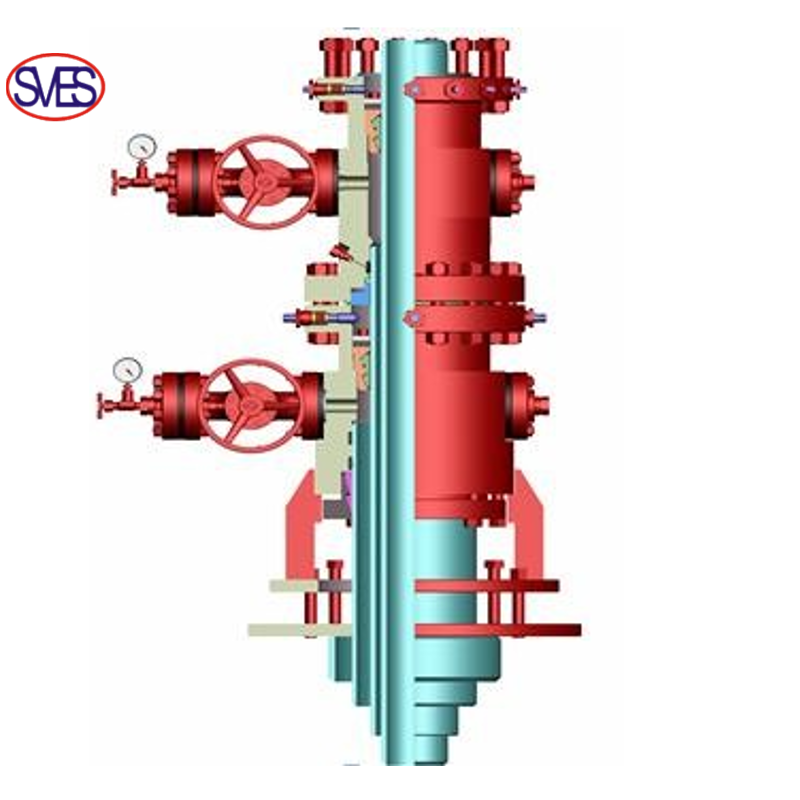

Subsea Christmas Tree has an extensive adaptability, it could meet the requirement of Blow well, Gas-lift well, Dual tubing, Chemical injection, Water injection, Annulus briging,etc.

| Working pressure | 10,000psi (69MPa) |

| Bore size | 3-1/16”× 2-1/16” |

| Product Specification Level | PSL3G |

| Performance Requirement | API 6A - PR2/API 17D |

| Temperature class | 2℃~120℃ |

| Material class | AA~HH(upon customer requirement) |

| Service period | 20 yrs |

| Water depth<200m | |

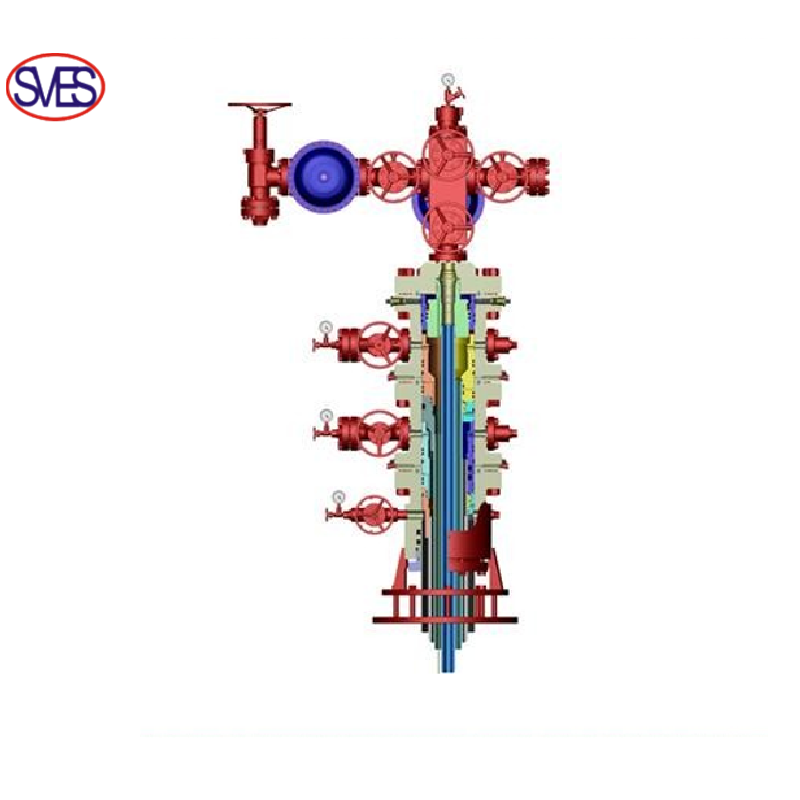

The dual tubing wellhead system adapts compact wellhead technology and produces oil from different layers seperately of the same well.The main structure is to place two comparallel tubing strings inside the same production casing, both tubing strings are separated by dual-tubing hanger. Dual tubing X-mas tree seated above with compact design & good sealing performance.

| Performance Class | Material Class | Temperature Class | Product Specification Class |

| PR 2 | AA ~ HH | K ~ V and X / Y | PSL 1~4 |

Fix drilled wellhead, connect wellhead casing string, seal and control the annular of casing, suspend tubing, control wellhead pressure and adjust flow rate, also induce oil into outlet pipeline, shut off oil well when necessary, and apply to acid fracturing, water injection and test service.

Consist of casing head, tubing head and Christmas tree

Apply to all kinds of casing, tubing programs and

connection forms

Feature reliable running, simple and convenient

operating and repairing

Can be equipped with (pneumatic) hydraulic safety

valve

Working pressure:2000PSI~20000PSI

Working medium:oil, natural gas, mud, including H2S, CO2

Working temperature:-46°C~121°C(Class LU)

Material class: AA、BB、CC、DD、EE、FF、HH

Specification level: PSL1~4

Performance level: PR1~2

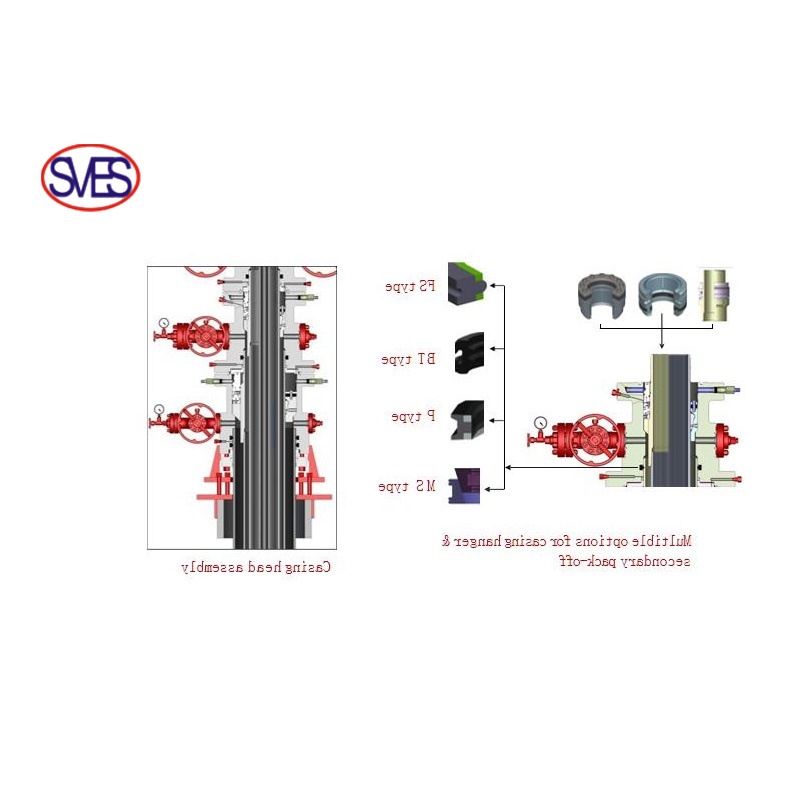

Straight-bore Design : 45°shoulder design with high load capacity

Side Outlet Connection Form :

Pipeline thread side outlet Threaded flange side outlet

Interchangeability of Casing Hanger: Casing hanger can interchange Interchangeability between slip

casing hanger and mandrel type hanger

Lockdown screw assembly:

Design complete set lockdown screw assembly Lock wear bushing

Protect the rise of casing hanger

Bottom connection form:

Weld type bottom connection

Threaded type bottom connection Slip type bottom connection

Connection Type of Casing Head & Surface Casing

Manufacture all kinds of casing thread, connect surface casing through pup joint

Weld casing head and surface casing on spot, apply to all specifications of casing.

Tighten locking bolt to slip clamp surface casing,

design with various type casing seal ring. The connection is firm and the seal is reliable

Casing hanger & secondary pack-off for casing head

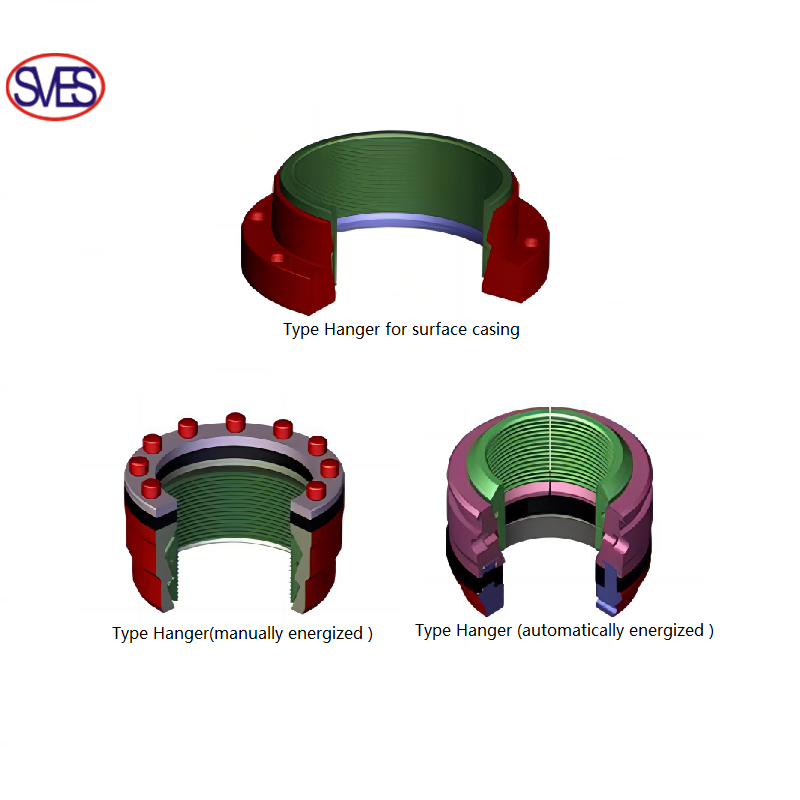

Type Hanger for surface casing

Consist of slip, slip bowl, etc.

Used for connecting casing head and surface casing through slip tighten casing with help of external force.

Applicable to XLBF casing heads of bottom connection.

Type Hanger (automatically energized ) Consist of slip, slip bowl and support base, etc.

Pack-off is automatically energized with casing weight.

Mating surface of slip and slip body design with

double limited position and one taper, this can lock casing easily and avoid destroying casing.

Applicable to XLBF casing heads and casing spools.

Type Hanger(manually energized )

Consist of slip, slip bow and hold down plate, etc.

Pack-off is manually energized.

Mating surface of slip and slip body design with double limited position and one taper, this can

lock casing easily and avoid destroying casing.

Applicable to XLBF casing heads and casing spools.

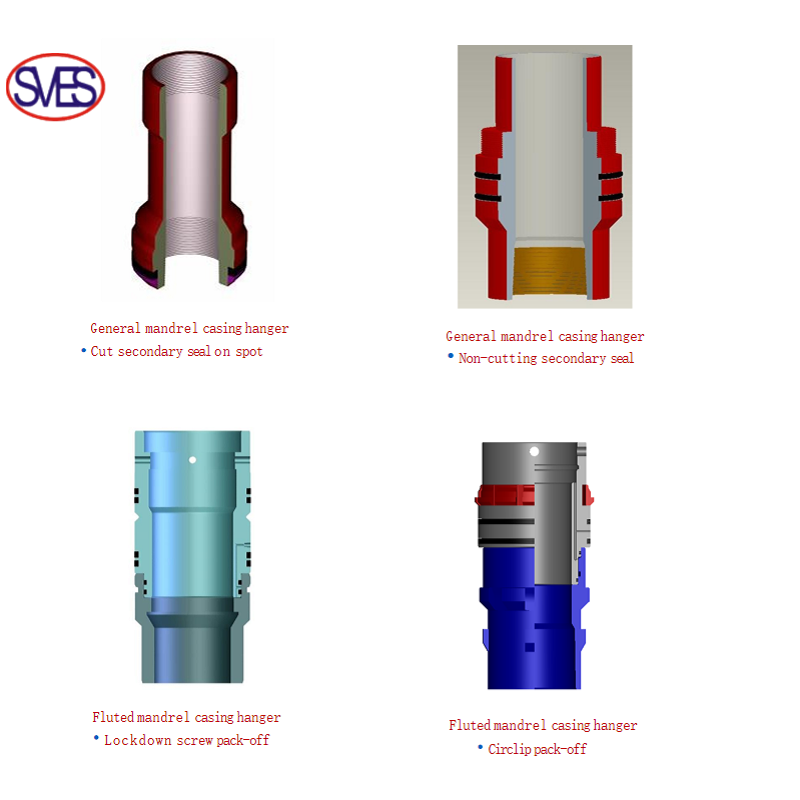

General mandrel casing hanger

Consists of hanger body, seal ring and retainer ring, etc.

Applicable to XLBF casing heads and casing spool, this is easy

operation and reliable seal.

Fluted mandrel casing hanger

Consists of hanger body and pack-off, etc.

Mandrel casing hanger use separate structure of hanging and seal.

Hang casing and cement before install seal assy.

Avoid damage seal assembly during hanging casing and cement.

convenient to replace seal assy.

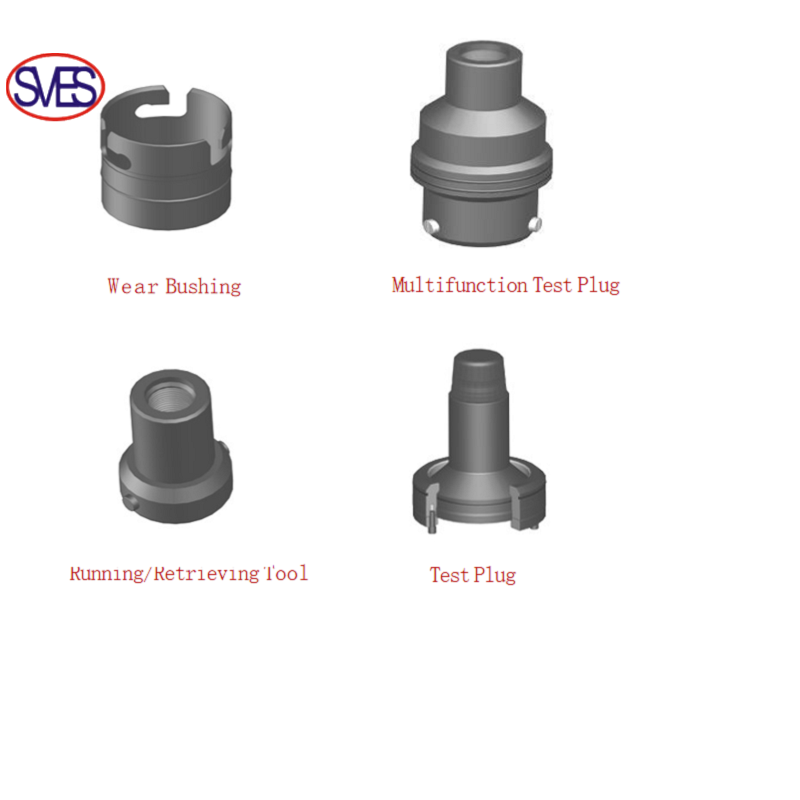

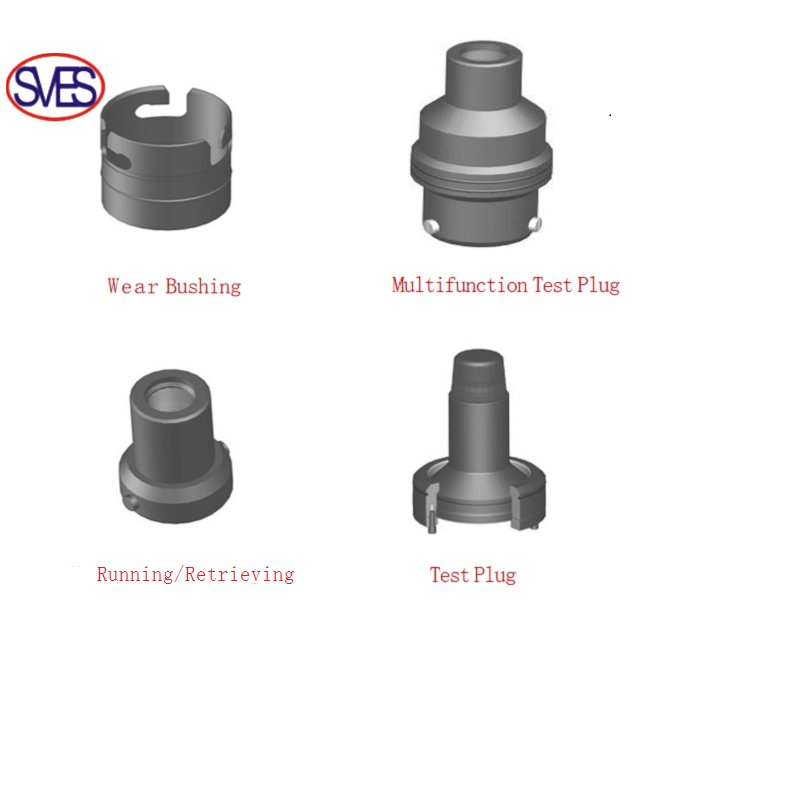

Wear bushing is used

for preventing cavity sealing surface of casing head and casing spool from damaging during drilling, and it is installed and removed by running & retrieving tool.

As running/retrieving tool of wear bushing, as well as test plug

Used for running/retrieving wear bushing.

The test plug is set on the shoulder of casing head, test seal performance of BOP, drilling spool and casing head through drilling pipe.

Meet the requirements of casing head of different specification through replacing the external test plug.

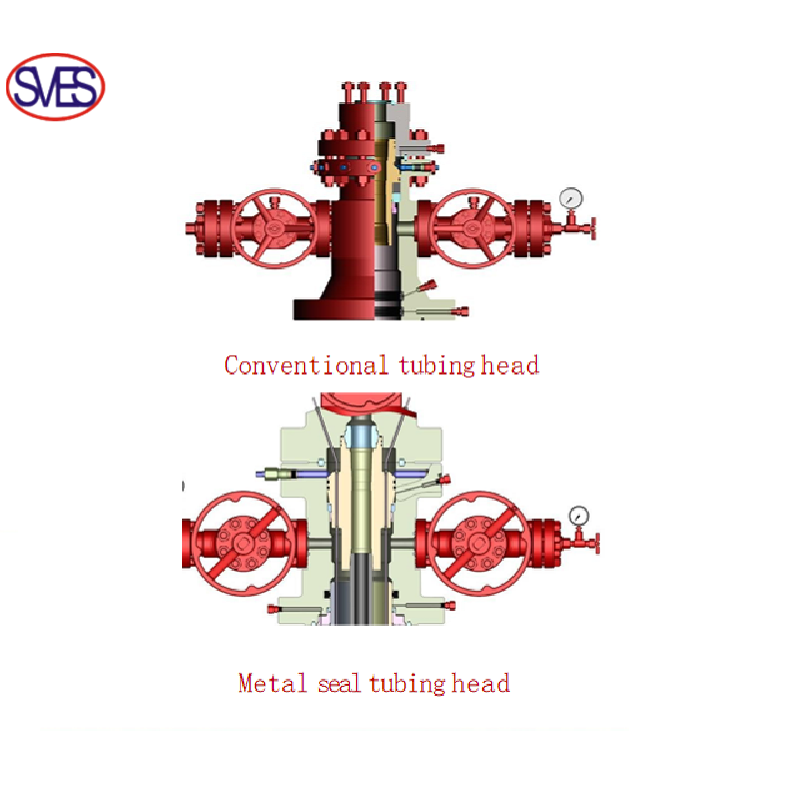

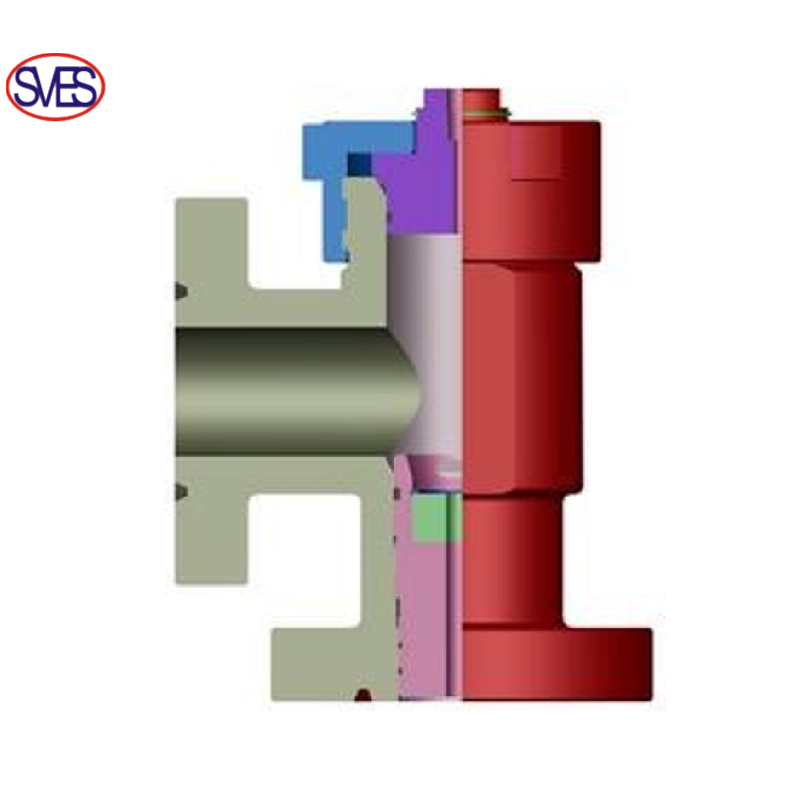

Standard Structure of Tubing Head & Christmas Tree

Tubing head with design of versatile straight-bore, can be installed tubing hanger with different specification.

Straight-bore Design

45°shoulder design with high load capacity

Side Outlet Connection Form

Threaded flange side outlet & Design with VR plug Lock Down Screw Assembly

Standardized design lock down screw assembly

Lock wear bushing Secondary Seal

·Design with secondary seal mechanism at bottom, ·

Rubber seal or metal-to-metal seal

Tubing Hanger and top flange can be fed through with

cable, or penetrated with power mandrel penetrator. or connect multiple joints for control pipeline.

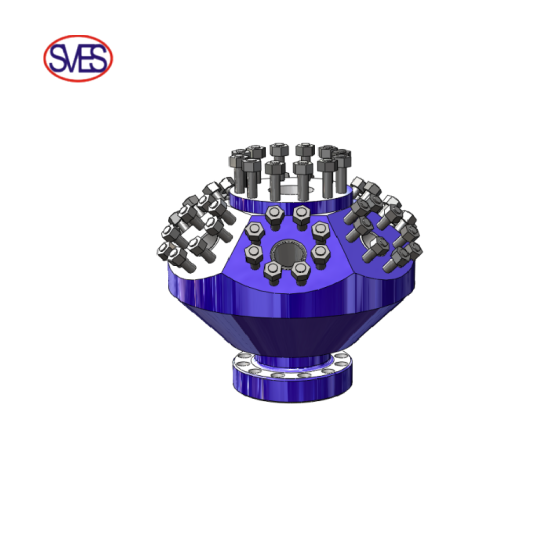

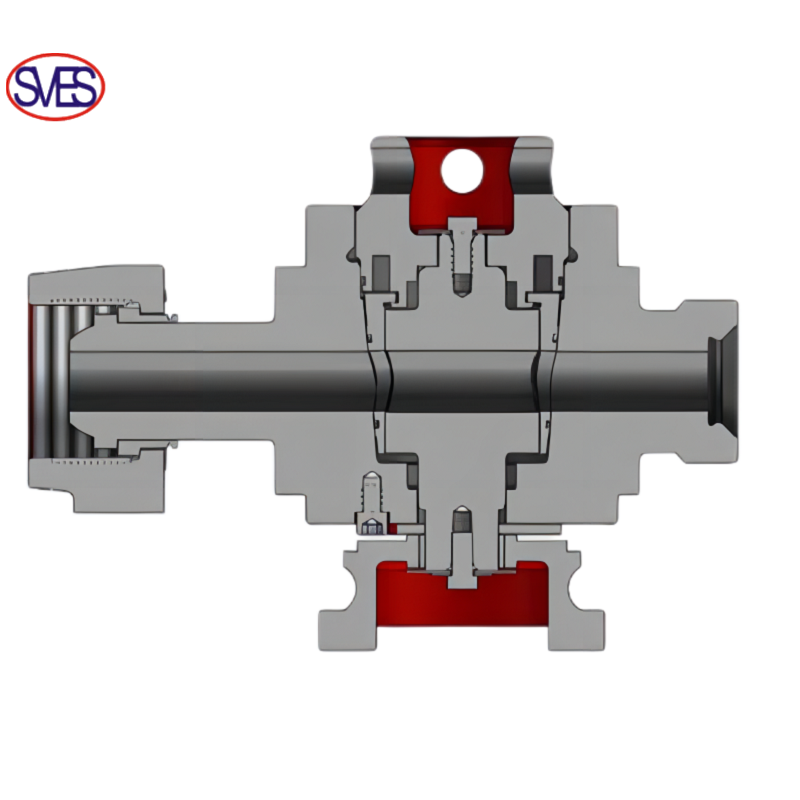

Special Wellhead—Multibowl Wellhead

Integral installed to save the installation time

No need to replace BOP during drilling.

Mandrel type casing hanger designed with mud circle groove.

Equipped with emergency slip to avoid casing being locked during lowering casing and mandrel casing hanger not at right position.

Apply to all kinds of casing and tubing program.

Can use different seal type.

Working Pressure :2000PSI~20000PSI

Working Medium: oil, natural gas, mud and gas

containing H2S, CO2

Working Temperature :-46℃~121℃(Class LU)

Material Class :AA、BB、CC、DD、EE、FF、HH

Specification level :PSL1~4

Performance Requirement :PR1~2

Special Wellhead—Dual Completion Wellhead

Can complete with different (pneumatic) hydraulic safety valve.

Designwithassemblinganddisassemblingdual tubing hanger quickly.

One well bore can exploit two different strata at the same time, and can control and operate separately.

Compactconstruction,convenientoperation,

reliable seal.

Apply to all kinds of casing and tubing program.

Working Pressure: 2000PSI~20000PSI

Working Medium: oil, natural gas, mud and gas

containing H2S, CO2

Working Temperature: -46℃~121℃(Class LU)

Material Class: AA、BB、CC、DD、EE、FF

Specification level: PSL1~4

Performance Requirement: PR1~2

Wellhead & Christmas tree Maintenance tools

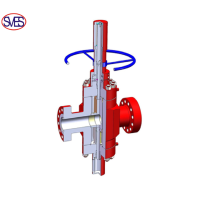

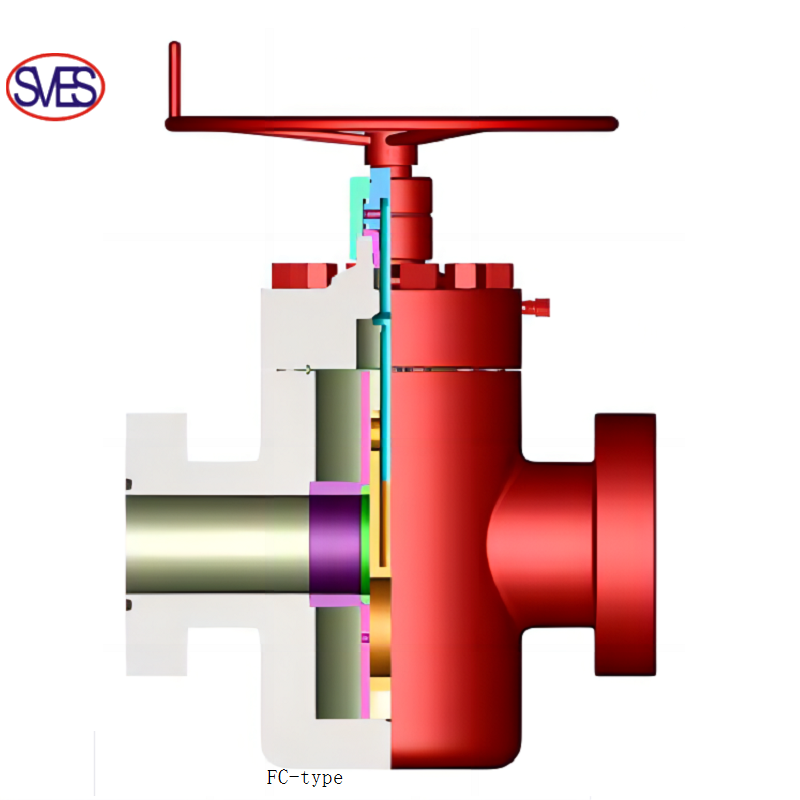

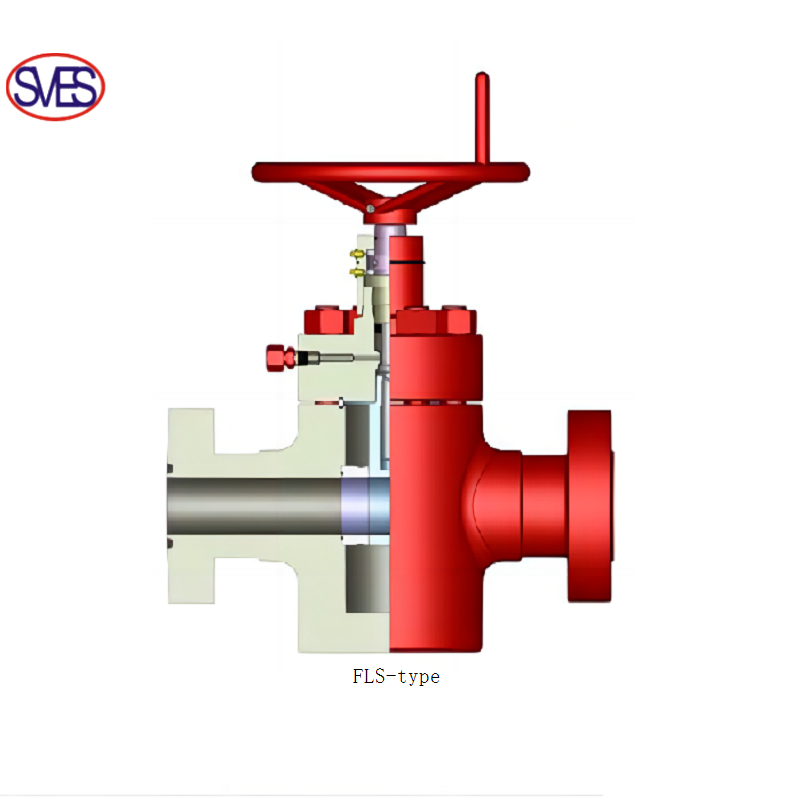

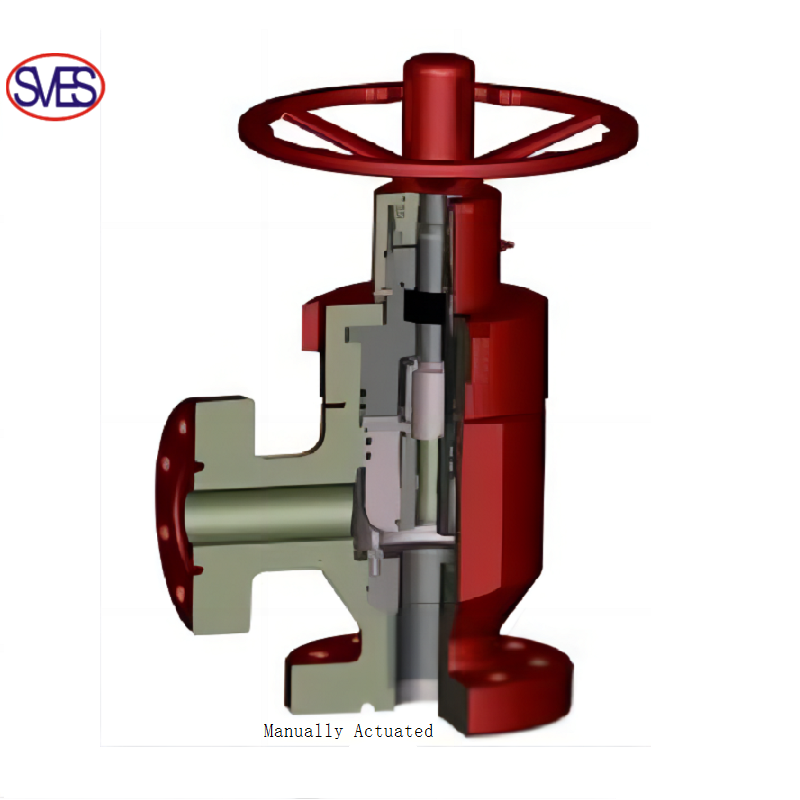

FC-type & FLS-type Manual Gate Valve

The stem packing uses teflon assy.

Metal-to-metal seal is used between bonnet body, and seat body.

The gate and seat ring is weld overlay with hard alloy.

The stem designed with back seal, can replace stem seal ring under pressure.

The bearing seat designed with special bean in order to supply sealant on spot.

One side of bonnet is designed with sealant injection valve in order to

supply sealant on spot.

Can complete with different pneumatic (hydraulic) actuator upon user’s

requirements.

Working Pressure: 2000PSI~20000PSI

Nominal Bore: 1.13/16”~9”(46mm~230mm)

Working Medium: oil、natural gas、mud and gas containing H2S、CO2

Working Temperature: -46℃~121℃(Class LU)

Material Class: AA、BB、CC、DD、 EE、FF、HH

Specification level: PSL1~4

Performance Requirement: PR1~2

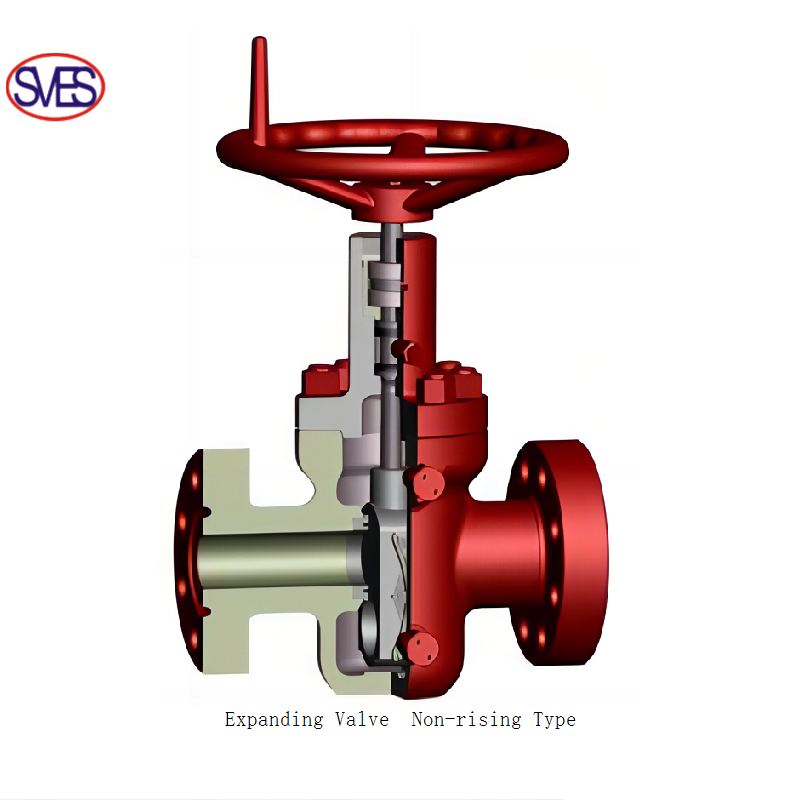

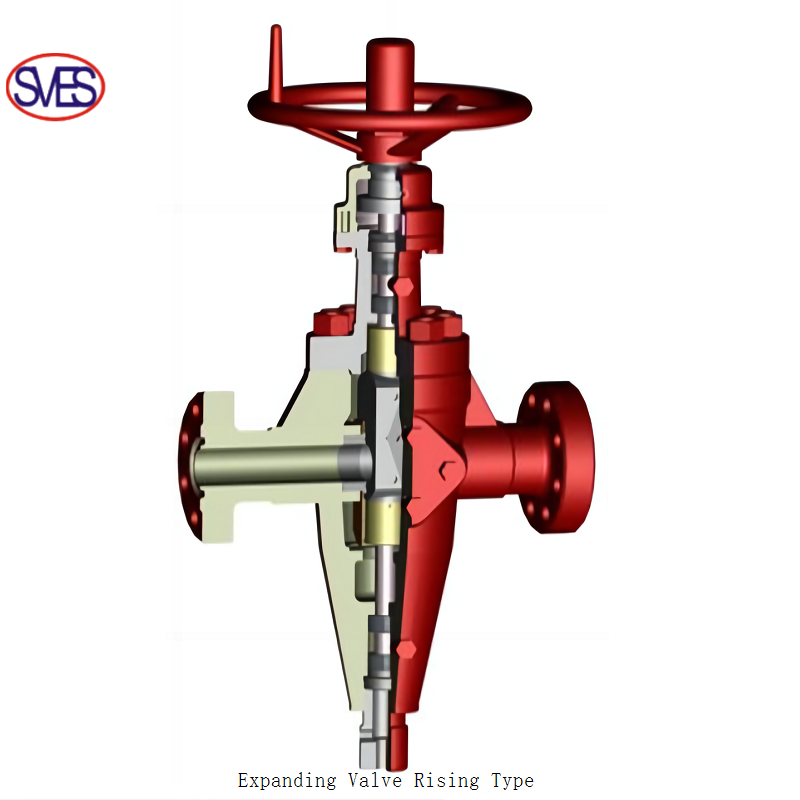

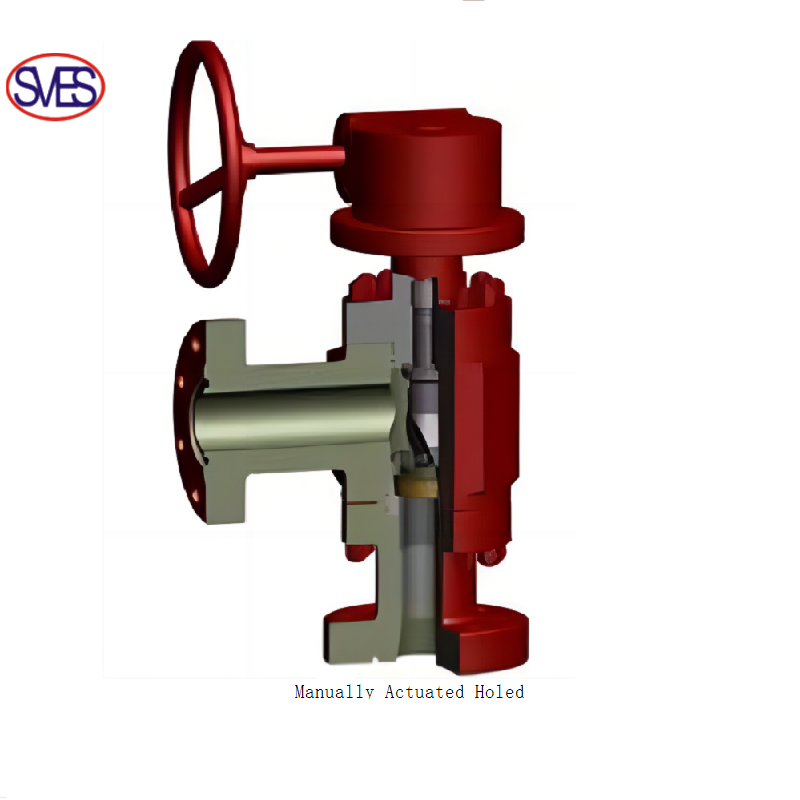

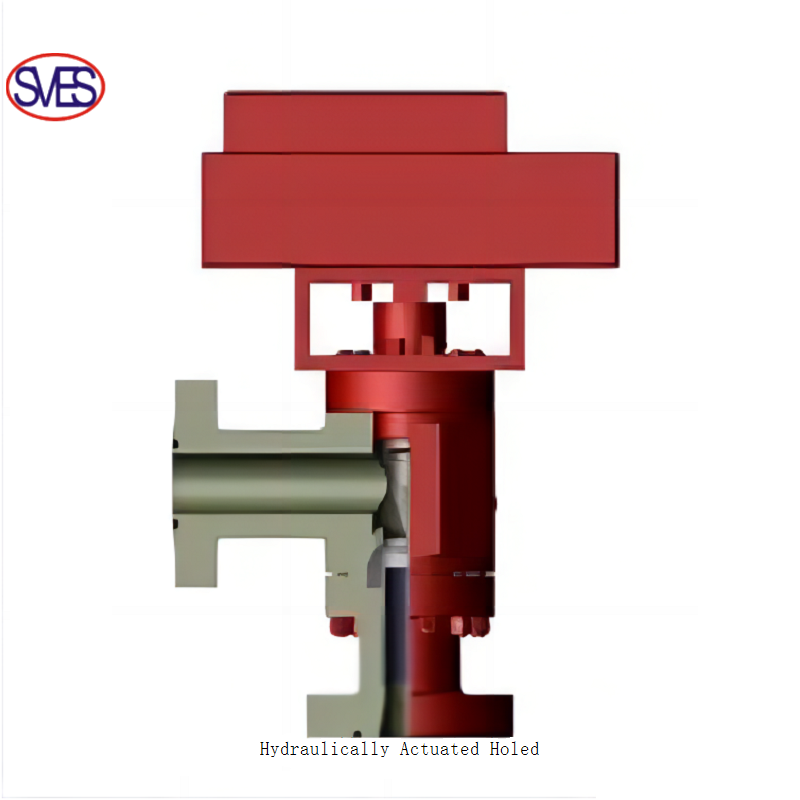

Full bore design eliminates efficiently pressure drop and vortex, and eliminates washing by solids in fluid.

Gate use expanding type structure.

Achieve low torque operation and low wastage during open and close.

Metal seal is used between bonnet and body.

Soft seal or metal seal is used between gate and seat.

Inject sealant through injection valve to improve seal performance.

Working Pressure: 2000PSI~10000PSI

Nominal Bore: 1.13/16”~7.1/16”(46mm~180mm)

Working Medium: oil、natural gas、mud and gas containing H2S、 CO2

Working Temperature: -46℃~121℃(Class LU)

Material Class: AA、BB、CC、DD、 EE、FF、HH

Specification level: PSL1~4

Performance Requirement: PR1~2

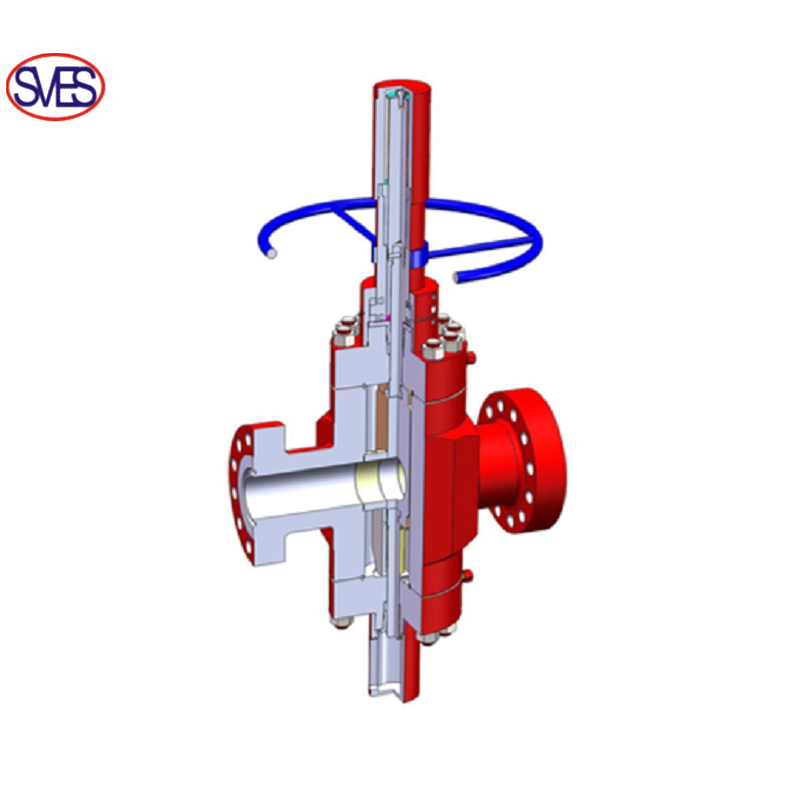

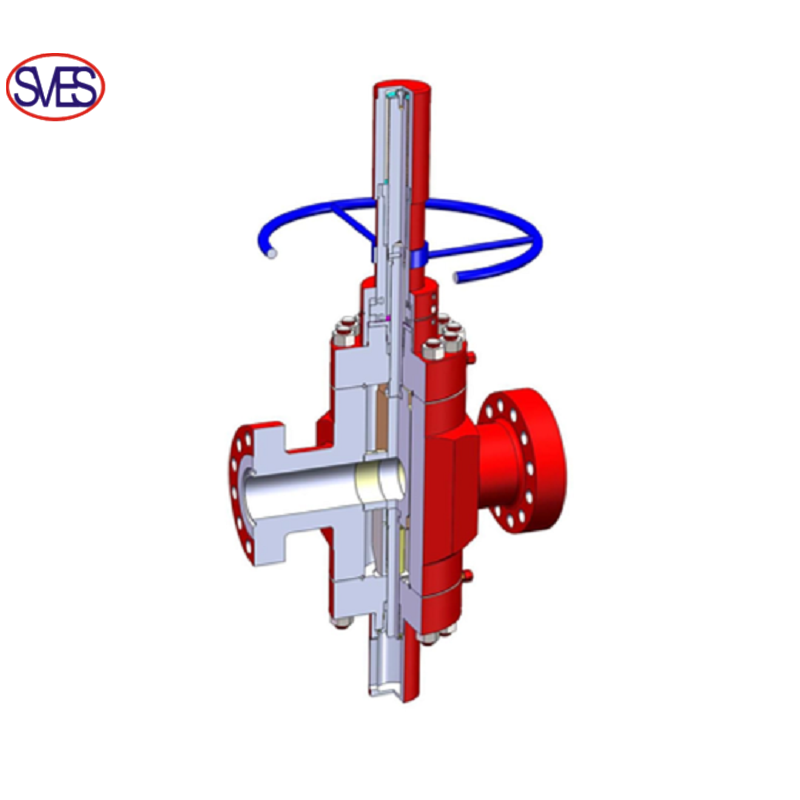

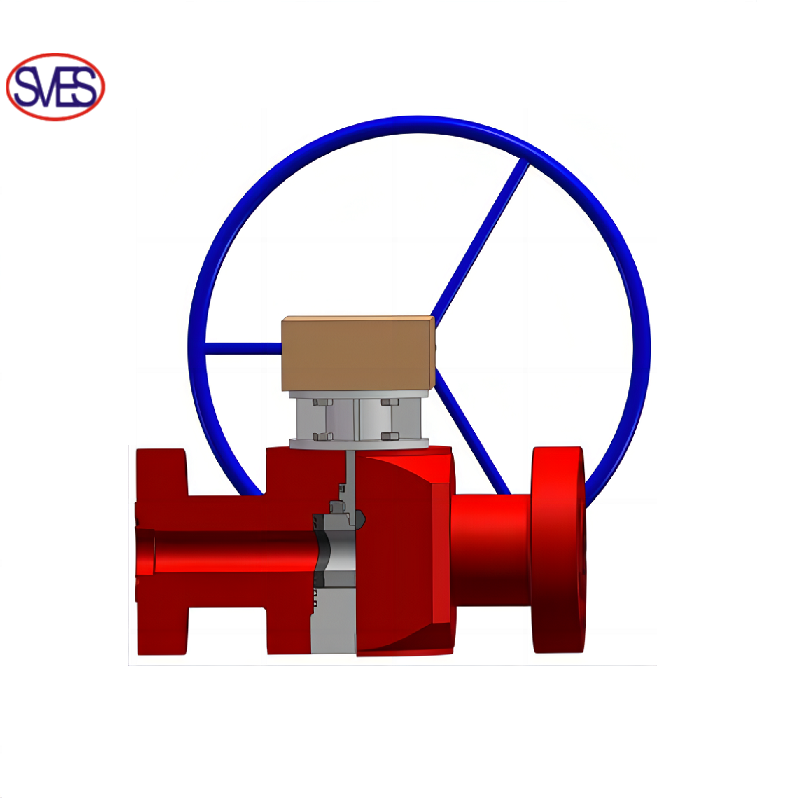

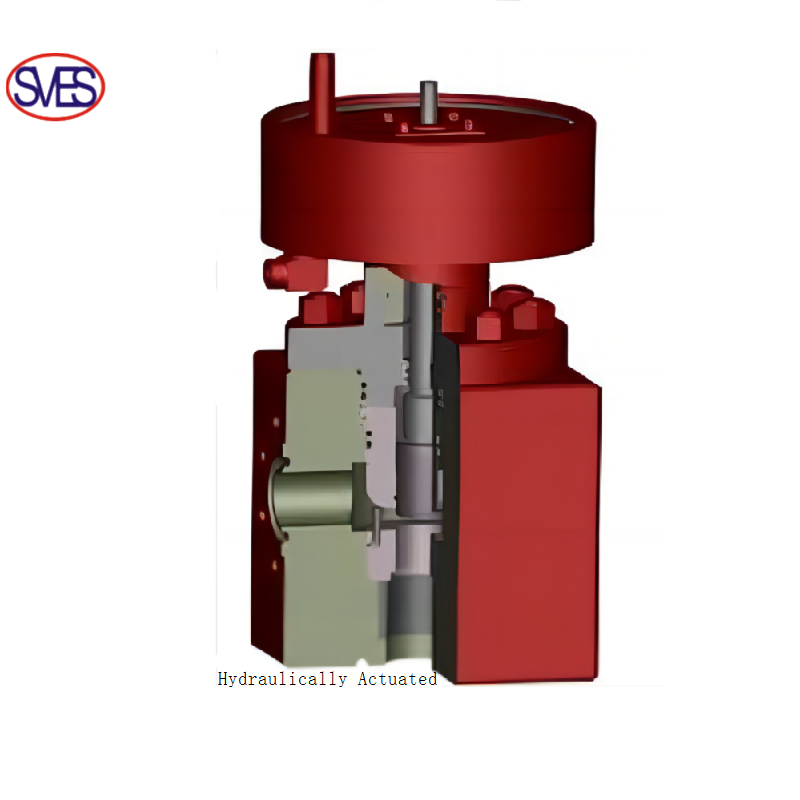

Ball screw operator Gate Valve

Ballscrewstructure

moment

Gate valve structure

Stem structure has the function of pressure balance and switch indication.

Apply to the structure of big bore high pressure valve.

Working Pressure: 10000PSI~20000PSI

Nominal Bore: 1.13/16”~9”(46mm~230mm)

Working Medium: oil, natural gas, mud and gas containing H2S, CO2

Working Temperature: -46°C~121°C(Class LU)

Material Class: AA、BB、CC、DD、 EE、FF、HH

Specification level: PSL1~4

Performance Requirement: PR1~2

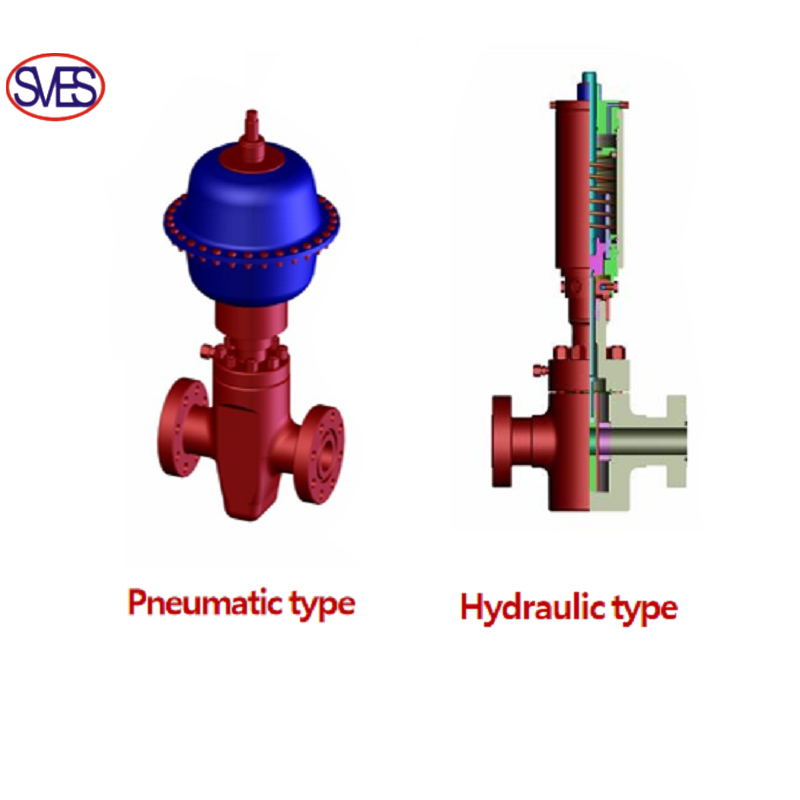

·When oil & gas is leaking or firing, used for security protect on well site.

·Have hydraulic safety valve and pneumatic safety valve per different driving source.

·With heat sensitive and high pressure explosion-proof

equipment.

·Have two parts of actuator and preparation valve, can replace and repair standard interface.

Working Pressure: 2000PSI~20000PSI

Nominal Bore: 1.13/16”~7.1/16”(46mm~180mm) Working Medium: oil, natural gas, mud and gas containing H2S, CO2

Working Temperature: 46℃~121℃ (Class LU)

Material Class: AA, BB, CC, DD, EE, FF, HH Specification Level: PSL1~4

Performance Requirement: PR1~2

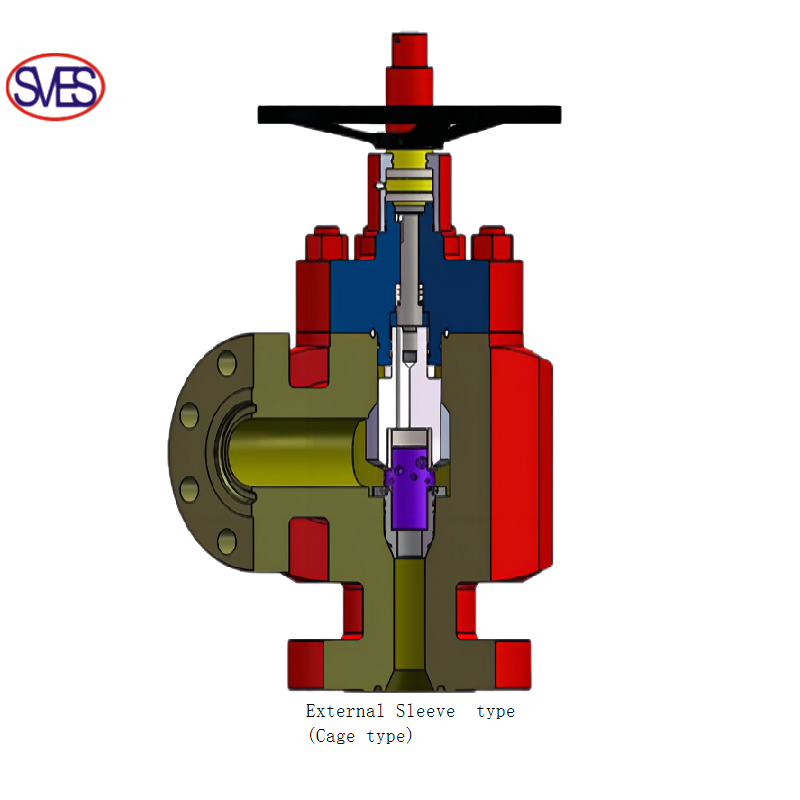

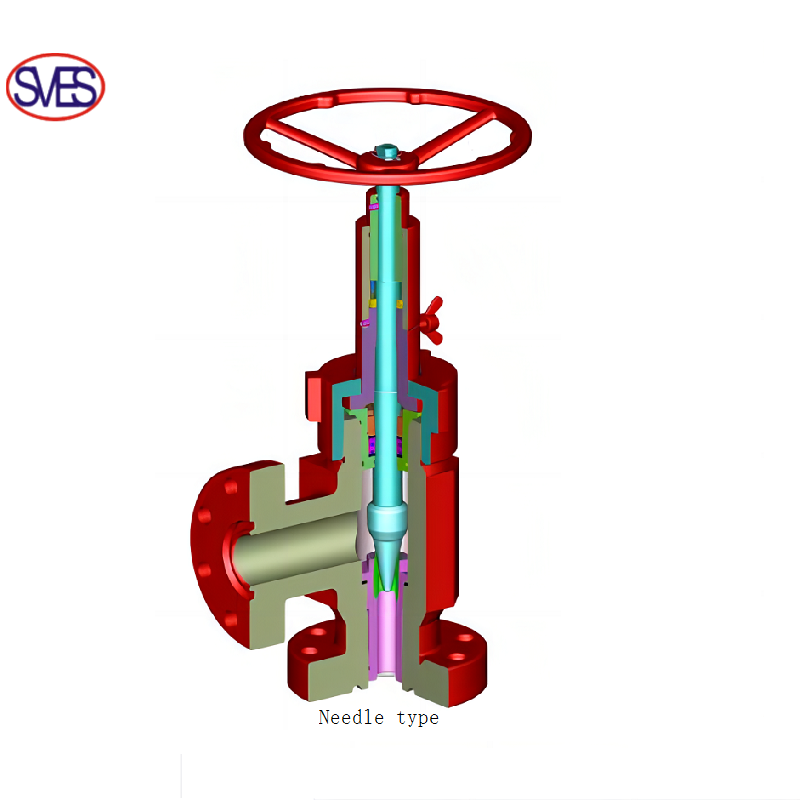

·Choke valves for needle type and external sleeve type are available for Christmas tree.

·The needle and core are made of hard alloy, with

performances of wearing resistance and washing resistance. The external sleeve choke valve has advantages of low switch torque, throttling and shutting fluid.

Working Pressure: 2000PSI~20000PSI

Nominal Bore: 1.13/16”~7.1/16” (46mm~180mm) Working Medium: oil, natural gas, mud and gas containing H2S, CO2

Working Temperature: 46℃~121℃ (Class LU)

Material Class: AA, BB, CC, DD, EE, FF, HH Specification level: PSL1~4

Performance Requirement: PR1~2

The bean orifice is made of ceramics or hard alloy, with performance of wearing resistance and washing resistance.

The bonnet connection form is union, which is more convenient to replace bean.

Working Pressure: 2000PSI~20000PSI

Nominal Bore: 1.13/16”~7.1/16” (46mm~180mm) Working Medium: oil, natural gas, mud and gas containing H2S, CO2

Working Temperature: -46℃~121℃(Class LU) Material Class: AA、BB、CC、DD、 EE、FF、HH Specification level: PSL1~4

Performance Requirement: PR1~2

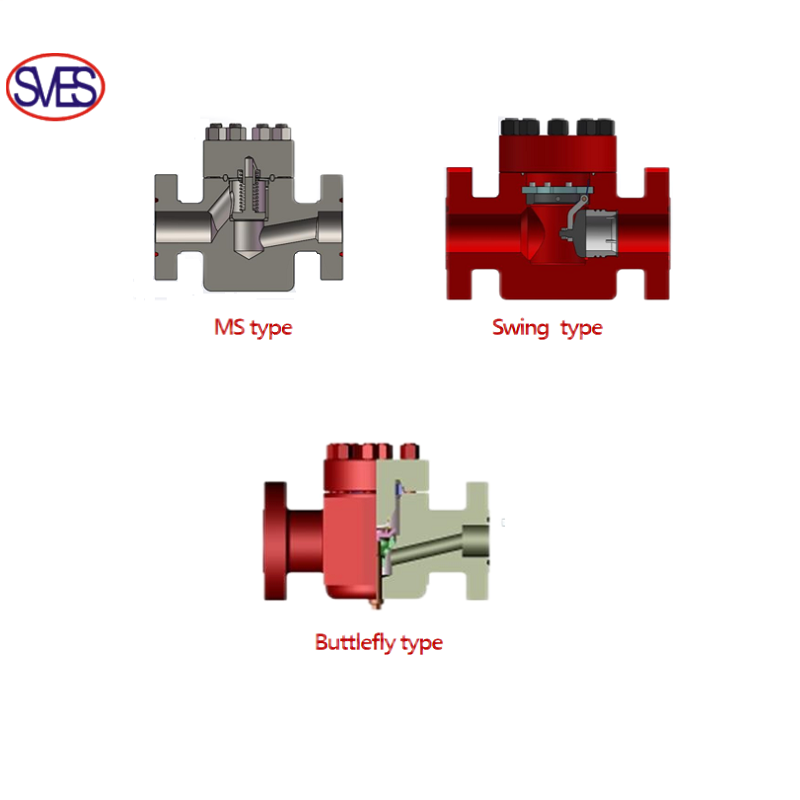

.The working medium flows in single direction.

.Working Pressure: 2000PSI~20000PSI

.Nominal Bore: 2.1/16”~7.1/16”(52mm~180mm)

.Working Medium: oil, natural gas, mud and gas containing H2S, CO

.Working Temperature: -46℃~121℃(Class LU)

.Material Class: AA、BB、CC、DD、 EE、FF、HH

.Specification level: PSL1~4

.Performance Requirement: PR1~2

.Closed or plunger-shaped rotary valve to close or open by turning 90 degrees so that the port on the valve plug can be same or separate direction from the port on the valve body.

.The shape of the plug can be cylindrical or conical. In cylindrical plugs, the channels are generally rectangular; for Conical valve plug, the channel into the trapezoidal. These shapes make the plug valve structure lightweight.

. Best suited for shutting off and connecting the medium as well as for shunting,

.Used for throttling depending on the applicable properties and the erosion

resistance of the sealing surface.

.Easy to install and maitenance. Working Pressure: 10000PSI~20000PSI Nominal Bore: 2”~4”

Working Medium: oil, natural gas, mud and gas containing H2S, CO Working Temperature: -46℃~121℃(Class LU)

Material Class: AA、BB、CC、DD、 EE、FF、HH

Specification level: PSL1~4 Performance Requirement: PR1~2

.The stem and core are made of hard alloy, with

the performance of wear resistance and wash resistance.

.Convenient to adjust flow.

. Working Pressure: 2000PSI~20000PSI

. Nominal Bore: 2.1/16”~4.1/16”(52mm~103mm)

. Working Medium: oil, natural gas, mud

. Working Temperature: -46°C~121°C(Class LU)

. Material Class: AA、BB、CC、DD、 EE、FF、HH

Drilling choke –Cylindrica type

.The stem and core are made of hard alloy, with

the performance of wear resistance and wash resistance.

.Convenient to adjust flow.

. Working Pressure: 2000PSI~20000PSI

. Nominal Bore: 2.1/16”~4.1/16”(52mm~103mm)

. Working Medium: oil, natural gas, mud

. Working Temperature: -46°C~121°C(Class LU)

. Material Class: AA、BB、CC、DD、 EE、FF、HH